América

0086 317 8312992

0086 317 8312992

horario de apertura

24 horas todos los días

24 horas todos los días

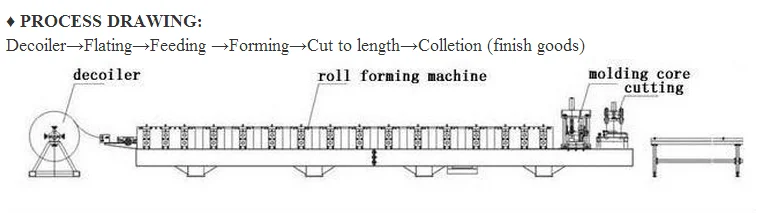

| Name | Botou light steel keel Metal furring channel house structure roll forming machine with punching hole |

| Configurations | Manual Uncoiler, Guiding Platform, 9 Shaft Strip Leveler, Main Machine Of Roll Forming, Hydraulic Motor, Pre-Punching Device,Pre-Cutting Device, Hydraulic Station, PLC Control, Supporter Table. |

| Control System | PLC Inverter Encoder Touch Screen |

| Main Frame | 400mm H-Beam |

| Total Power | 7.5 kw |

| Power Supply | 380V, 3-Phase,50Hz |

| Forming Speed | 12-24m/min |

| Roll Station | 14 stands |

| Decoiler capacity | 3.5 tons |

| Roller Diameter | 80mm |

| Effective Width | 80-300mm |

| Feeding Thickness | 0.3-1.2mm |

| Backboard Thickness | 20mm |

| Cutter Standard | GCr12 |

| Roller Standard | Gcr15# |

| Overall Size | About 8500×1000×1400mm |

| Total Weight | About 3.2 T |

| Custom | According to customer's requirements |

Established in 1998. Kexinda has accumulated rich experience in producting tile roll forming machine. Near 20 years' development has made Kexinda the most powerful roll forming equipment supplier in Northern China. We are now staffed by over 200 people.The two production regions in Kexinda span an area of 50 thousand m2. We have established 5 large workshops, including plants for spare parts machining, machine welding, assembly, andsurface treatment.

1:How to play order: Inquiry---confirm the profile drawings and price----confirm the PI---arrange the doposit or L/C---then OK

2:How to visit our company:

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour),then we can pick up you.

Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours),then we can pick up you.

If any questions,you can call me mobile phone at any times: WhatsApp:0086-15132794725

3:If you want to get more pictures or videos of the machines,I can send them to you by WhatsApp/Wechat:+8615132794725.